Bottle to Bottle Facility (B2B)

Phoenix Technologies - Bowling Green, Ohio

IPS was hired as the design build contractor Phoenix Technologies’ new 66,000 square-foot B2B (bottle-to-bottle) facility.

This facility brings in 10,000 lbs or 2.5 tons per hour of recycled plastic bottles to then turn them into plastic pellets. First, recycled plastic bottles are sorted into silos, then they are grinded down into flakes, which then goes through a machine that creates the pellet. The pellets are loaded on trucks and sold to plastic bottle manufacturers such as coca-cola.

Each large silo is 65 feet tall, 19 feet in diameter, and holds 15,591 cubic feet of flakes that are later processed into the pellets. The four pellet silos, just a tad smaller, are 54 feet tall, 13 feet in diameter, and hold 6,443 cubic feet of finished pellets.

The new pre-engineered building houses all the equipment for this process but there is also offices, a cafeteria, locker rooms, maintenance/utility room, storage, and meeting rooms. Our team is handled the sitework/concrete, building erection, mechanical, electrical, data and controls.

- 60,000 SF facility size

- Design Build

- 13 months duration

- $30 million project value

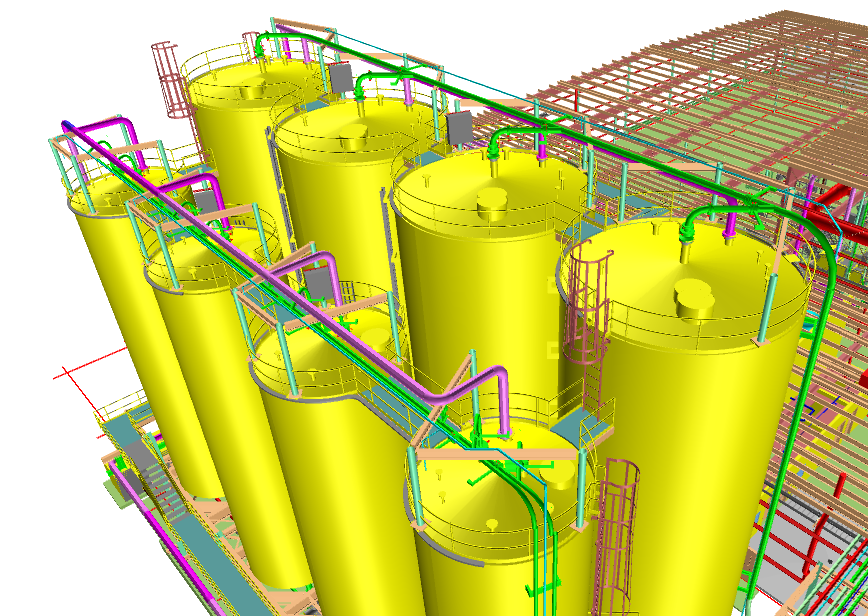

Virtual Design & Construction Group

IPS VDC 3D modeled all of the process, dust collection, and utility piping on this project. Highlighted in the picture is the prefabricated piping on top of the 65′ and 54′ silos. We utilized our 3D scanner to verify the connection points on all the silos after the silos were set. We brought this point cloud into our design model to spool 100% of the piping in our fab shop. These spools were then flown up with a crane and connected with either press fit or bolt-up connections. The allowed us to complete this section more safely, quicker, and more efficiently than the alternate of performing nearly 100 welds over 50 feet in the air.