IPS has considerable experience working in a 3D/BIM (Building Information Modeling) design and construction environment. We utilize the latest BIM software and technology to design, create fabrication deliverables, and assist in our field installation. These models can be created from scratch internally or we will upgrade an engineer’s conceptual model up to LOD 400.

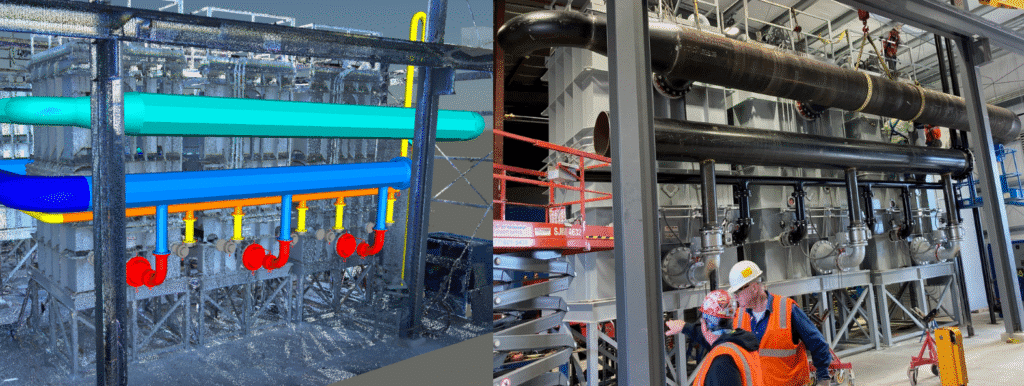

A large part of our process is incorporating our 3D laser scanner to verify the accuracy of the design model, existing conditions, and to ensure we install per the model. The individual scans taken on site are registered and tied together to create a complete one-to-one scale point cloud. From this point cloud, the customer and our team have the ability to take measurements, view existing site conditions, check interferences, 3D model new proposed work around these interferences, and much more. Our scanner measures 500k points per second within a 1/16″ accuracy up to 400 feet from the scanner. These two photos above, show the BIM model (left) and the actual piping installation photo for the customer (right). We perform 3D scanning for internal use as well as a standalone service to be handed over directly to the customer or engineer.

Confidential Client

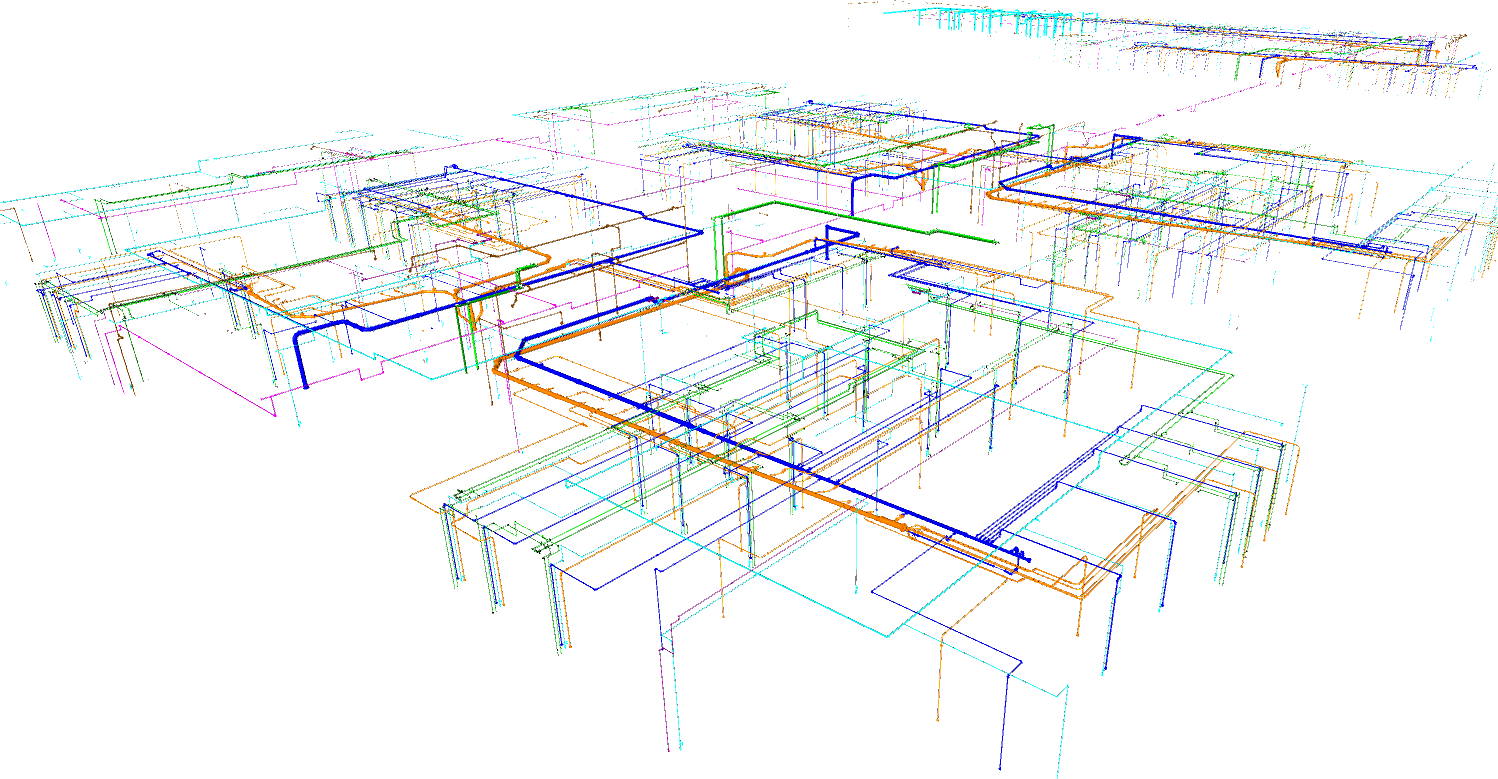

- 80,000 liner feet of pipe ranging from 1/2″ to 16″ diameter.

- Over 1,400 pipe spool drawings

- 1,400+/- pipe support drawings for steel needed to support the process piping.

3D modeled and created 71 different fabrication packages for all of the process piping, utility piping, and the solid steel supports. Each fabrication package consisted of individual pipe spool drawings, spool maps, pipe support drawings, detailed smaller 3D models, bill of materials, field layout drawings, and budgeted manhours.

Phoenix Technologies

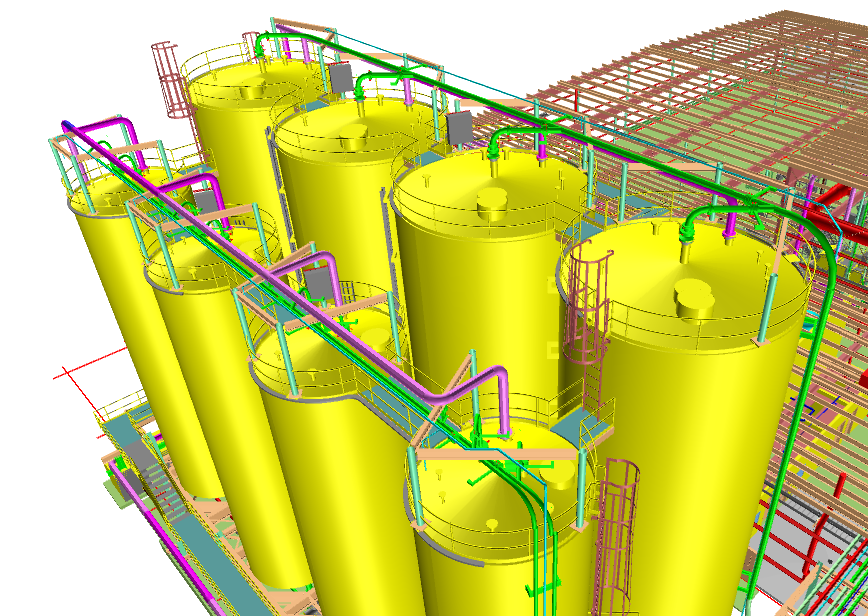

3D modeled all of the process, dust collection, and utility piping. Highlighted in the picture is the prefabricated piping on top of the 65′ and 54′ silos.

Read more….

IPS also utilizes our robotic total station to assist in field layout. Points are loaded into it from PDF, CAD, or CSV files. This total station is controlled through a tablet and provides more efficient and accurate workflow to layout underground piping, equipment, anchor bolts, hangers, penetrations, and much more.